Product

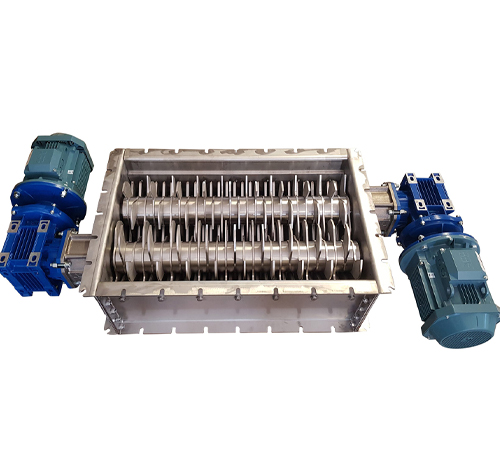

Lump Breaker System

Manufactured by ODE TECHNOLOGIES

Efficient Size Reduction & Deagglomeration for Powders and

Granules

Lump Breaker Systems are engineered to break down agglomerates and lumps in bulk

materials,

restoring free-flowing characteristics and preventing blockages in downstream processes.

ODE TECHNOLOGIES offers robust, low-maintenance lump breakers suitable for a wide range

of

materials including chemicals, minerals, fertilizers, food ingredients, and polymers.

Key Features

- - Heavy-Duty Rotor with Replaceable Tips

- - Adjustable Clearance for Desired Fineness

- - Low RPM, High Torque Design

- - Mild Steel / Stainless Steel Construction

- - Inlet Feeder & Outlet Chute Options

- - Safe Access Doors & Interlocks

- - Simple Maintenance & Easy Cleaning

- - Optional Dust Extraction Port

- - Capacity Range: Small Batch to High Throughput

- - Integration with Conveying / Feeding Systems

We can customize this system as per your

requirement.

Enquire Now